3D printing is one of the most innovative techniques in the crafting industry today, and that includes its place in the cosplay community. It’s also a highly technical process that requires a lot of special equipment, software, and high quality 3D print filament. The filament is the material that the printer uses to recreate 3D models, and the characteristics of the filament will ultimately affect the final product. While there are multiple filament options you can use with a 3D printer, perhaps the most popular filament for cosplay is ABS plastic, (sometimes just called ABS).

If you’re able to play around with ABS and 3D printing, or even master the skill, you can create some really spectacular, sculptural objects for your cosplay. In this post, we’ll discuss the basics of ABS plastic and 3D printing for cosplay along with the benefits and challenges to expect when using this material and technique.

Best Uses for 3D Printing in Cosplay

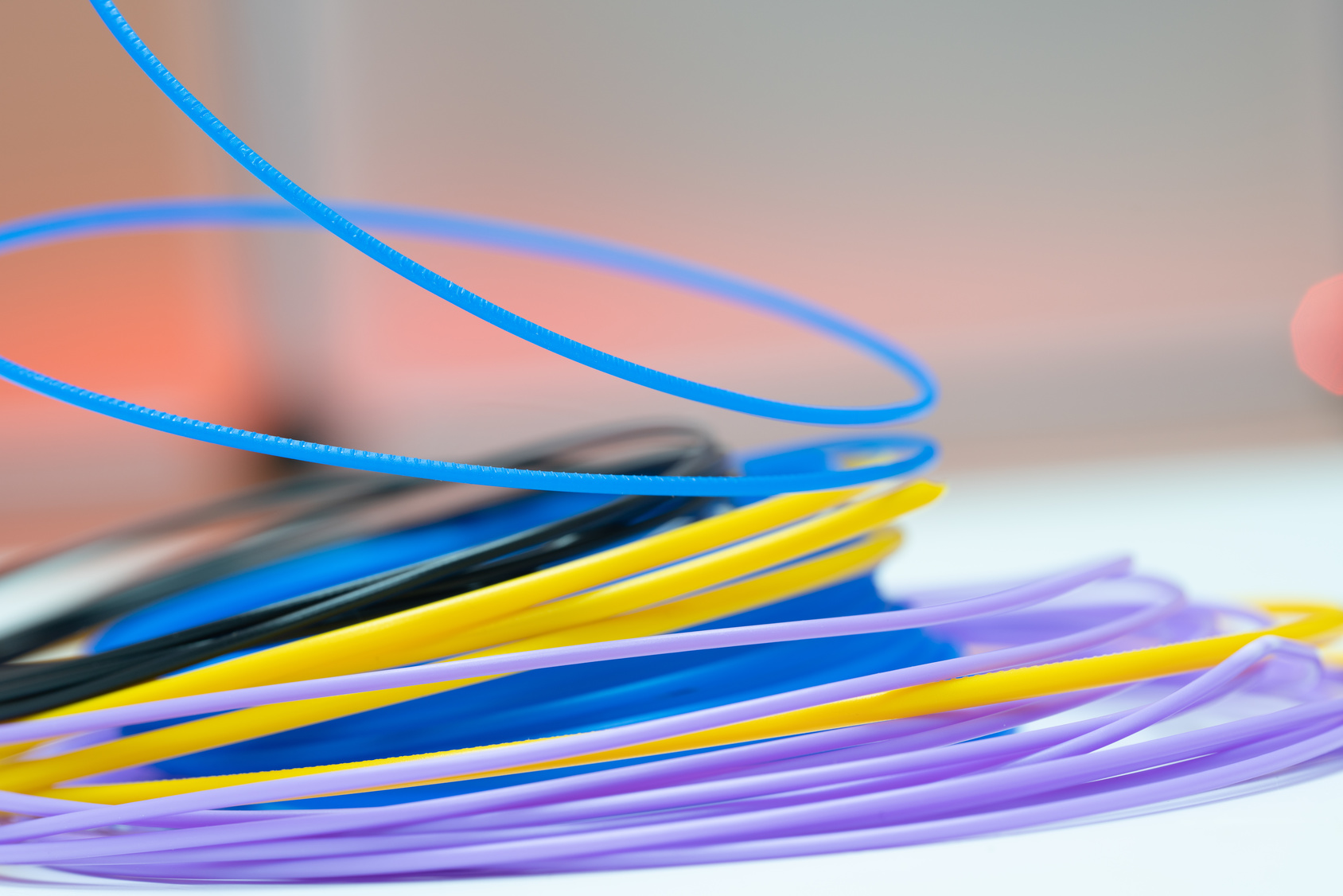

Since 3D printers started gaining popularity in the craft and hobby industries, makers of all kinds have found a wide variety of uses for the technology. In short, a 3D printer takes an electronic model and then automatically builds that design out of a filament like ABS. ABS for printing is generally sold in a wire format on a spool. Therefore, if you’ve got access to a printer and ABS for it to build with, you can make just about any three-dimensional object you might need for your cosplay. Of course, this comes with certain limitations, but cosplayers have created a wide variety of items from ABS, including armor pieces and suits, weapons and weapon pieces, elements like horns and wings, and much more.

Just like there are a few filaments to choose from, there are also several different 3D printers on the market that all come with different capabilities and strings attached. For the most part, many 3D printers are more suited to creating relatively smaller costume pieces because of limited space in the machine. However, larger cosplay pieces that cannot be printed in one singular piece can be broken up into smaller components using special 3D design software. These pieces can be printed one at a time and then assembled by hand outside the printer. Most small details, decor objects, and other small items can be printed all at once after being modeled in the software. While many of these objects can be made out of multiple types of 3D filament, ABS plastic is generally regarded as the best option for cosplay specifically for a variety of reasons we’ll discuss in the next few sections.

Benefits of ABS Plastic

There are several reasons why ABS plastic is an ideal material for 3D printing. Here are some of the benefits for using it with a 3D printer.

- When used for 3D printing, ABS can help you create incredibly accurate, detailed, and exact objects based on electronic designs and images.

- ABS is tougher and more durable than other popular filaments, such as PLA, which is often used for other types of crafts and hobbies. Therefore, a cosplay piece made of out ABS with withstand more general wear and tear while you’re wearing or carrying it.

- ABS also withstands heat after being printed while PLA does not. This means your cosplay would be safer to wear outdoors in the sun or transport in a hot car, for example.

- ABS pieces can be assembled with a few different adhesives, including super glue, two-part epoxies, a 3D print pen, or putty fillers, so you can choose the glue that works best for you.

- ABS creates a relatively smooth print that also shows definition and detail well.

ABS Plastic Challenges

However, there are some challenges to working with ABS as well. Here are some of the cons you should be aware of:

- In general, 3D printing is a long process that takes some time. Both the modeling stage and the physical printing will require some patience.

- At the same time, 3D printing in general takes some technological skill and understanding in many cases. It’s an entirely different process because the sculpting is automated, but that doesn’t necessarily mean all you have to do is press a button and print. Researching and perhaps even attending workshops on 3D printing will help beginners learn what it takes to actually 3D print their cosplays.

- 3D printing requires a sizable investment, no matter what machine or filament you choose. If you can’t afford your own machine, there are printing services you can pay for, or perhaps a makerspace near you that has a machine you can use, but either way, it tends to be more expensive than working with something like foam.

- ABS in particular, can warp if it gets too warm before it completely cools after being printed. Until your piece is cool, you’ll need to make sure it stays at a moderate temperature.

- The edges of your ABS piece will likely need sanded down, as a small lip or plastic tags can develop during printing.

- When you assemble ABS pieces, you might find that the print is slightly off at the seams in places. The best advice for solving this challenge is to match up the most detailed part of your cosplay and then use putty to fill in the gaps on the plainer sides and sand them smooth.

Printing or Sculpting?

There’s a little bit of a debate among some cosplayers when it comes to 3D printing: because it’s automated and created mainly using computers, does that mean that 3D printed cosplays are “cheating”? Considering how much work still goes into designing, programming, and then assembling and decorating your 3D printed pieces, most cosplayers do agree: it’s not cheating at all. It’s simply a different process for sculpting your 3D costume elements. When you’re printing with ABS plastic, the design is what’s hands-on while the actual production is automated. The only difference when you’re working with something like foam, thermoplastic, clay, and more is that you’re shaping and carving your material by hand. Either way, cosplay takes a lot of work and creativity, and your methods all depend on your preferences and what materials you have available to you.